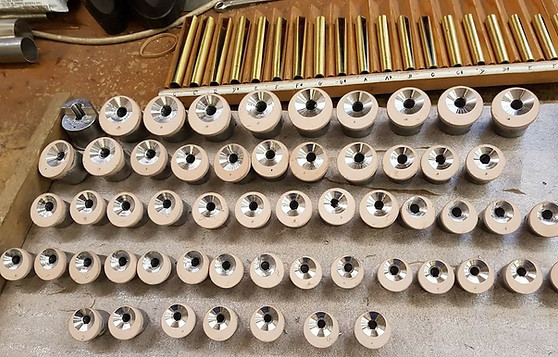

Hand made reed pipes

Trumpet, tromba, oboe, clarinet? We can meet your needs

From creating the boot to shaping the tongue, to fashioning the resonator, the complex process of crafting a reed is carried out by hand by our skilled team at Shires Organ Pipes.

Our craftsmen are experienced in making reeds pipes of any type or size, so please speak to us to see how we can help with your particular project.

A reed pipe comprises a brass tongue which vibrates against a tubular shallot. A wooden wedge holds the reed and shallot in place and the assembly hangs from the underside of the block into the tapered pipe boot.

A phosphor bronze wire, inserted though the boot, holds the reed against the shallot. A tuning knife is used to move the wire to change the length of the tongue, regulating the pipe's pitch.

A resonator meets the upper opening of the shallot and extends above the boot. Wind entering the boot travels over the reed, causing it to vibrate against the shallot to produce sound. The air then passes into the resonator, which focuses the sound wave.

The tonal characteristics of reeds are determined by several factors, not least the interaction between shallot and tongue. A voicer will take care in shaping the tongue's curve, as this controls how it beats against the shallot.

The shape of the shallot, whether cylindrical or tapered, greatly affects the timbre, as does the shape of the 'cut' and the closed-end. The type of block in which the reed assembly sits can also affect the sound.

Scaling is important in determining the final tone colour, though it is not as important as in flue pipe construction. Reed pipe resonators simply reinforce certain partials of the sound wave, the air column inside the resonator is not the primary vibrator.

But the shape of the resonator is important: an inverted-conical resonator, typical in a trumpet rank, produces more harmonics than a cylindrical resonator, such as a clarinet.